-

- For new flooring: The surface should be hard, level, dry and clean with normal water absorption.

- For new mortar: Ensure that the grout is maintained dry for 7 days per 1 cm of thickness before paving.

-

- For the old foundation: need to check the surface and chisel out the weak spots, peeling off the surface.

-

- Re-fill the holes on the mortar or brick glue

- Surfacing the surface

- Leave the ground dry for 48 hours before paving

-

- Cleans dust particles, deposits or grease on the substrate

-

- When paving in hollow or windy conditions or in hot dry areas, the substrate must be moistened to saturated (no water absorption) before paving.

-

- The substrate should be dry with a maximum moisture content of 3%

-

- When paving on old brick, check the adhesion of the bricks. Remove the uncertain brick and re-brick at that location.

-

- Unstable substrates such as gypsum or gypsum plasterboard should have a reinforcement and bolt connection to each of the 900 cm2 (or 30 x 30 cm)

-

- Fill the joint between the wood panels or fiber cement panels with silicone sealant

- Use fiber reinforcement to cover the upper slits

-

- To paste a tile on a wooden surface or cementitious sheet, weber.prim 2 should be scoured before placing the tile to increase adhesion of the glue and prevent the water from the glue from penetrating into the substrate.

-

- When bricks are overlapped, weber.prim 2 should be removed before bonding, which increases adhesion to glue.

TILING WITH TILE ADHESIVE

- Tiling with traditional mortar affects the tiles to be dislodged

Common issues and queries you can face

Brick is peeling and breaking

When tiling in the traditional way, tiling into pieces behind the brick (as shown) will create many holes under the brick to make bricks break easily. In addition, water will leak through these gaps and damage neighboring areas. In addition, the adhesion of the tile adhesive will be reduced when the construction method is not suitable such as plastering into pieces as shown, or using traditional fly. This will cause the tile to peel off after a period of use. Another case is the large size tiles used in the old method used traditional mortar immediately after the floor will cause the phenomenon of bricks and bricks break easily at the corners.

Bricks don't stick to conventional bonding surface

When soaking bricks in water, the amount of water dipped in the brick will make the water component change and tile adhesive. Soaking will reduce glue adhesion and cause slippage when wall tiling.

SOLUTION

- Always use tile adhesive for tiling and choose the type of product that will suit the tile as well as the application. See details here.

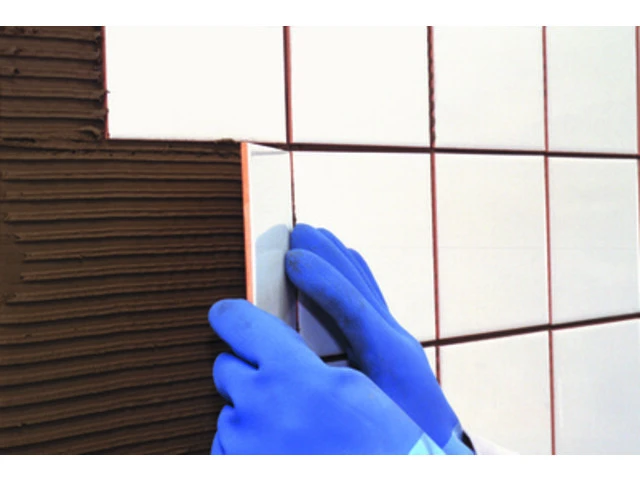

- It is advisable to use a notched trowel when using tile adhesive and avoid plastering in pieces as this will cause bricks to break easily.

- The work of the floor screed should be complete and dry before applying tile adhesive to the large size tile.

Necessary products for this solution

PREPARATION

APPLICATION

Find all our products near you in more than 2000 outlets